Custom Tooling Expertise: Elbex’s Precision from Start to Finish

In manufacturing, precise tooling is an absolute must, especially when creating custom extrusions. Outsourcing tooling may seem like a good idea, but this can often lead to delays and poor quality control. Instead, working with Elbex, which offers in-house tool and die design and custom tooling capabilities, can ensure you get the efficiency and quality you need.

The Elbex Advantage: On-Site Tooling for Unmatched Efficiency

In-house tooling provides several noteworthy advantages for your project. First, doing everything in-house eliminates outsourcing costs, which can result in significant cost savings. Doing everything in-house also streamlines the production process, dramatically reducing lead times, minimizing delays, and improving the overall project workflow.

All of this enables us to improve the delivery schedule for your finished products and ensure that deadlines are met. Perhaps most importantly, however, doing everything in-house allows us to maintain meticulous control over the entire process, ensuring that finished seals and gaskets meet quality standards.

Elbex’s Tooling Capabilities: From Design to Production

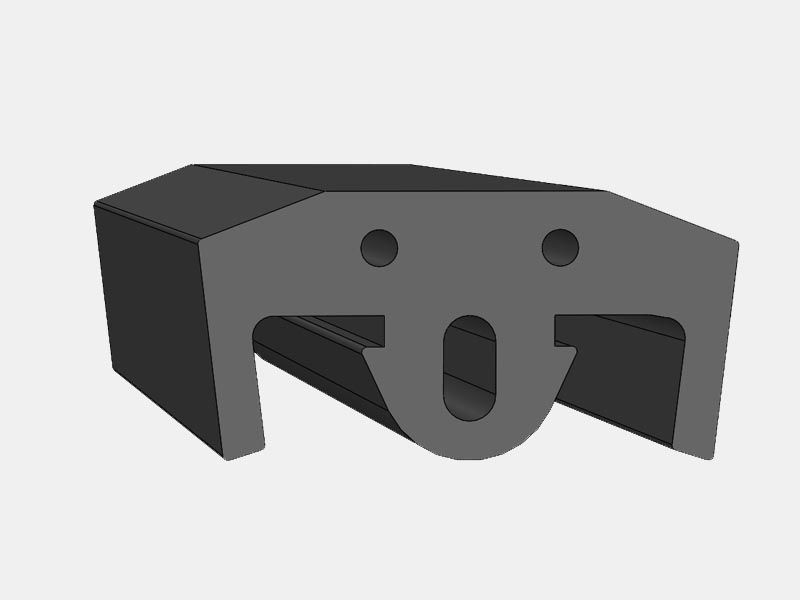

At Elbex, we offer a wide range of custom tooling capabilities that benefit the entire manufacturing process. We use AutoCAD to create precise 2-D models, which are the foundation for accurate tooling. Our engineers also leverage their industry expertise to optimize tool and die design for specific materials and profiles.

During production, we use wire EDM to create intricate shapes and complex profiles with exceptional precision, as well as sinker EDM to create complex cavities and shapes in dies and molds. Precise cuts and finishes enabled by these processes ensure consistent quality for rubber seals and gaskets, even with intricate designs.

The Elbex Process: A Seamless Experience

By keeping everything in-house, we offer a streamlined experience from start to finish. We begin by assessing your needs and defining tooling requirements during an initial consultation. After this, our engineering team gets to work, using AutoCAD to design and model the tooling.

Once the design phase is complete, we can begin manufacturing in-house, using wire EDM, sinker EDM, and other processes as needed to achieve custom tooling. Rigorous quality control measures are implemented throughout production so that both tool and die design, as well as finished seals and gaskets, meet all necessary quality standards.

With our on-site custom tooling capabilities, Elbex can deliver a seamless experience at every stage of the project, while achieving the consistent quality you need. Contact us today to discuss your custom tooling and extrusion needs.