Custom Extrusions for the

Water Control Industry

ELBEX designs and manufactures custom rubber extrusions for the water control industry, including the engineering, plant construction, and equipment supply subsectors. Our rubber extrusions play a vital role in any application in the water industry in which a reliable barrier solution is needed. Our engineering team will work closely with you to figure out the right extrusion for your specific application, taking into consideration the various environmental factors that will affect the integrity and longevity of your extrusion product.

Unique Solutions for Water Treatment Plants

The National Sanitation Foundation (NSF) has created standards for drinking water and the systems that treat it. However, even with those standards in place, many municipal facilities don’t use NSF-61-approved materials when it comes to gaskets and other rubber extrusions. We’ve heard from many treatment facility operators that gaskets are often the last thing thought about, but the thing that can cause the most issues. We’ll help you select the right extrusion and material to ensure a lasting solution.

Here are a few examples of applications within the industry:

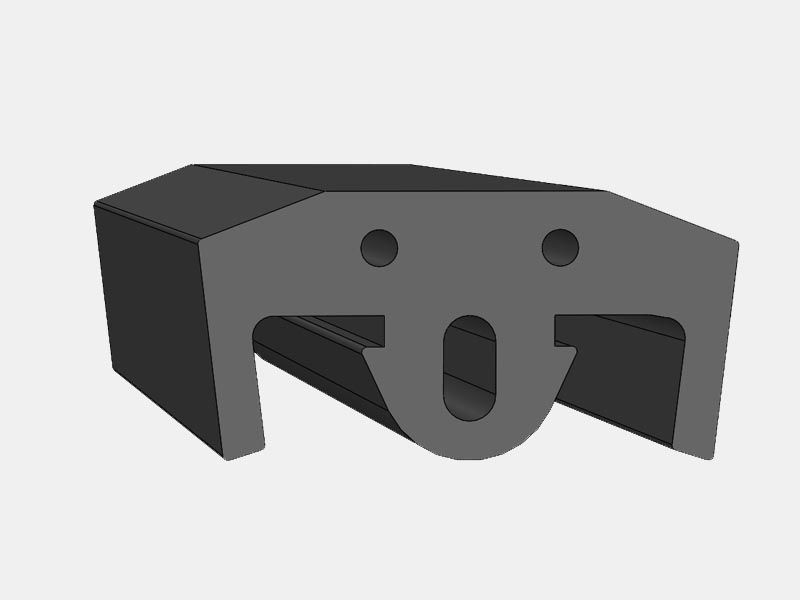

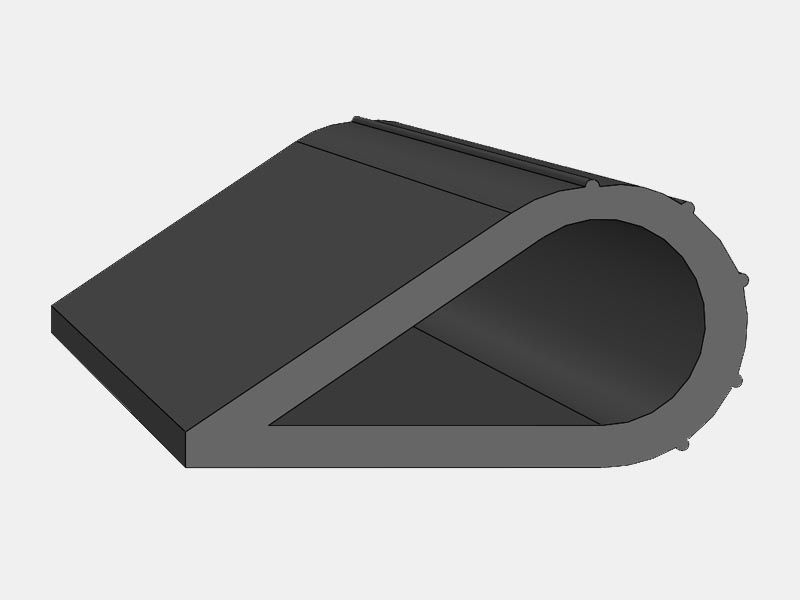

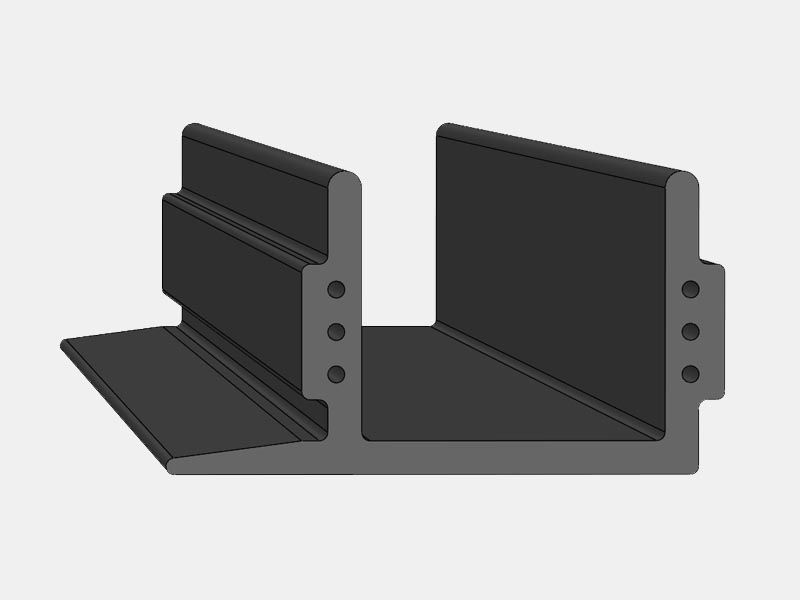

- Rubber gate seals for industrial water filtration systems

- Gaskets for drinking water treatment systems

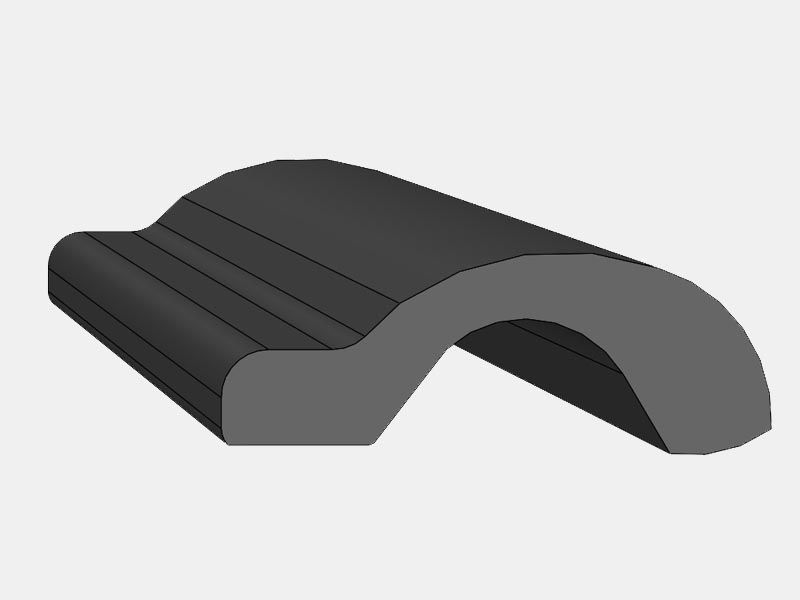

- Diffuser membranes

Extruded Rubber Gaskets and Seals

Gaskets and seals are very general terms for any type of profile that is intended to fill a gap or void and create a barrier. Both gaskets and seals are commonly used for:

- Water resistance

- Air barriers

- Tight seals

- Vibration elimination

- Securing components

Gaskets and seals are often lumped together into the same category because they both provide a strong sealing force, but their functions are slightly different. Seals are used to connect and seal two moving parts, while gaskets are commonly used as static seals between two flat surfaces set in place. Materials used for either product vary, but are often dictated by the specific application and corresponding environmental and chemical exposure.

Extruded rubber gaskets and seals from ELBEX provide superior stability and protection compared to other types of expansion joints because of our team that’s dedicated to quality through the entire extrusion manufacturing process.

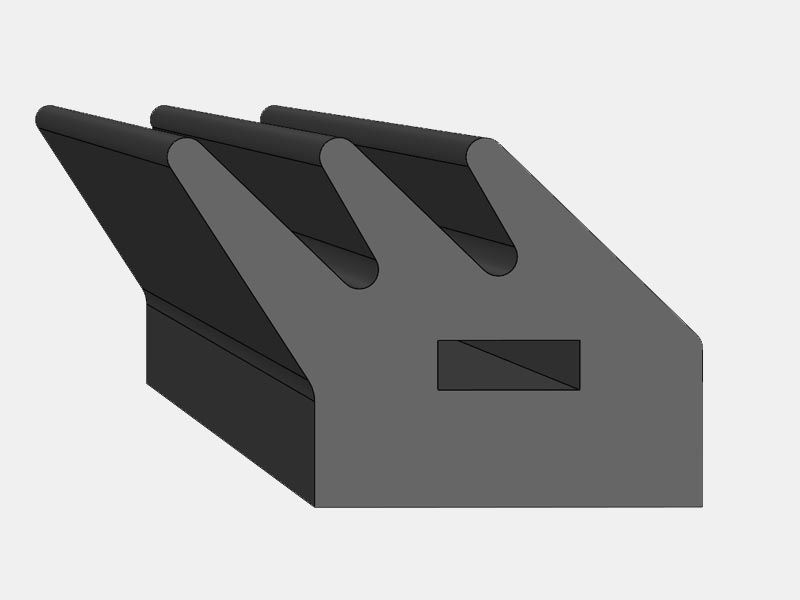

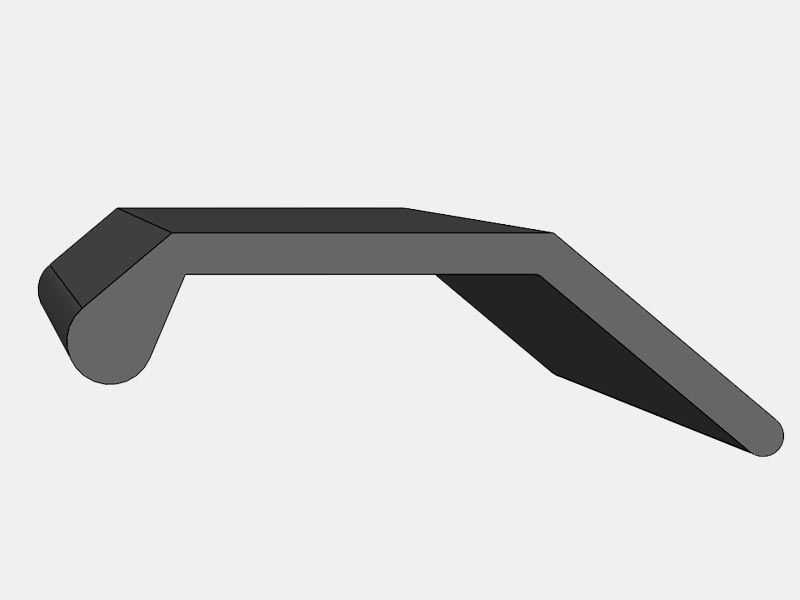

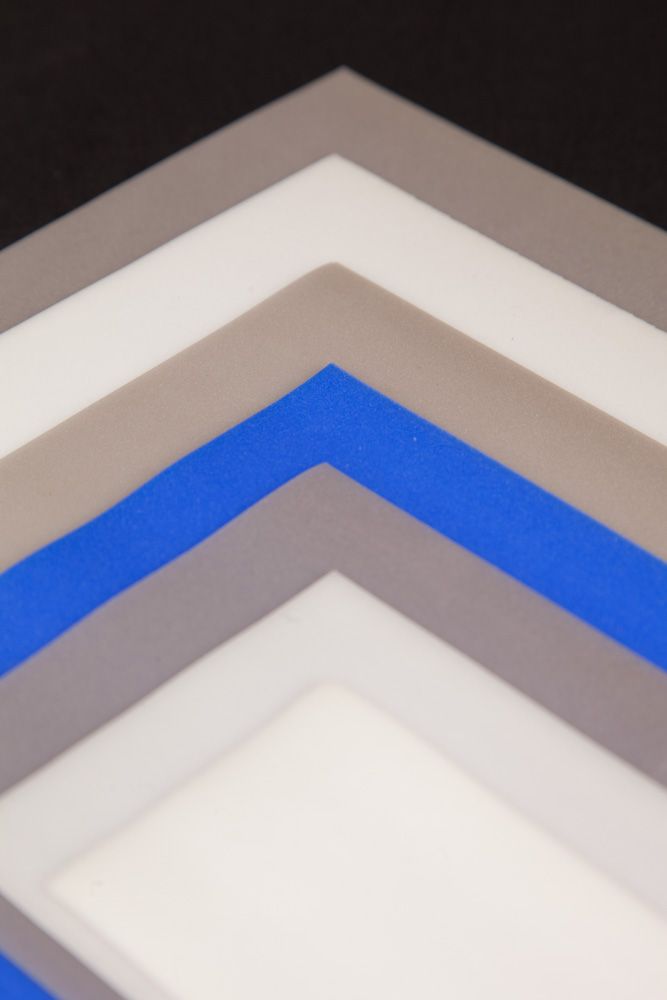

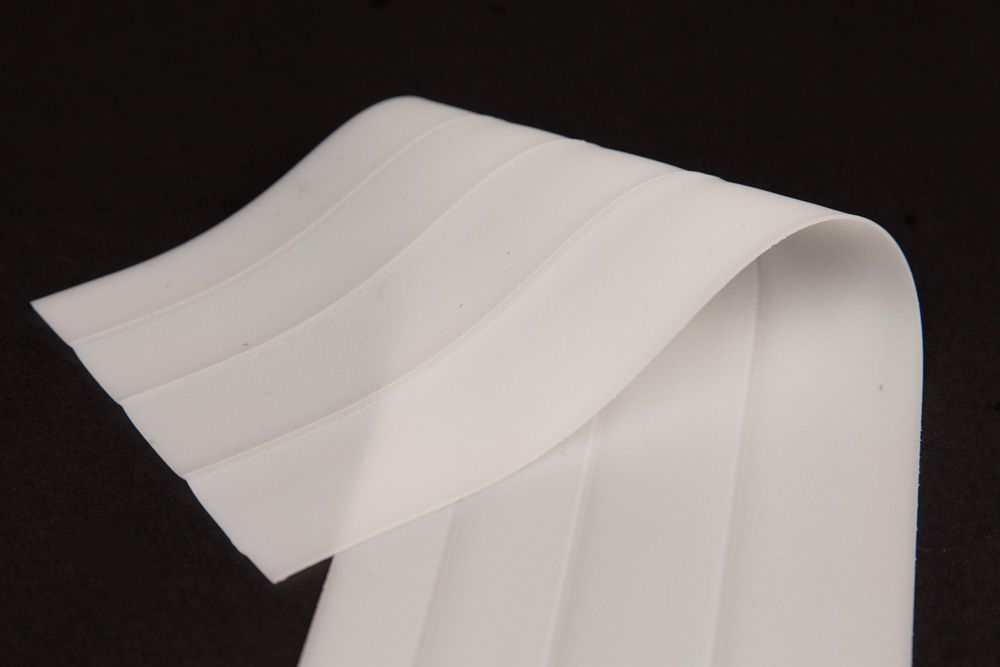

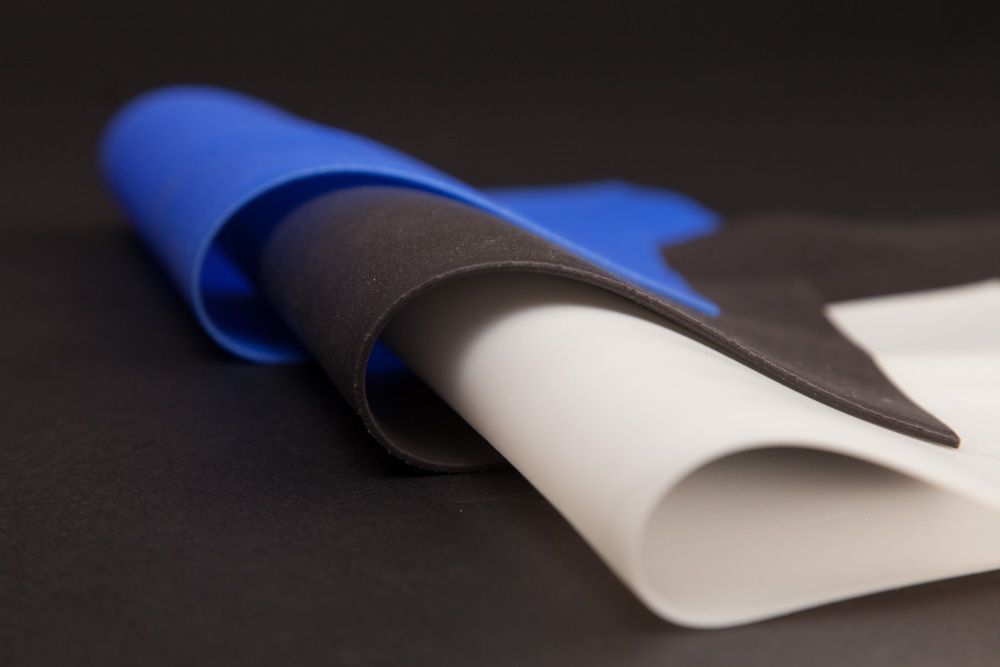

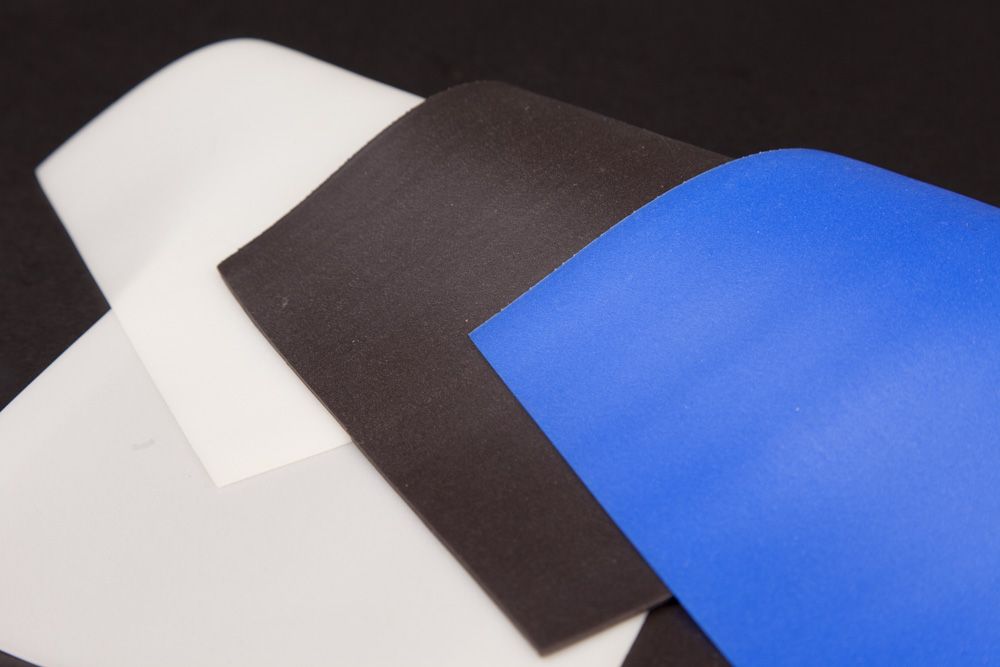

Custom Extruded Silicone Sheeting

We take pride in our ability to deliver a custom manufactured product to meet your specification requirements. Based on our extensive capabilities, nearly any design can be met. Below are strictly a few examples of profile types that ELBEX has the capability to produce. For more information please reference our capabilities page.

Standard translucent sheeting in various widths typically available for immediate shipment. For detailed pricing please see our silicone sheeting pricing page.

Engineering Resources to

Support Your Project

ELBEX Corporation is committed to providing top-notch support to its customers during the design and manufacturing process. We understand that the success of our clients is directly tied to our ability to provide them with the highest level of service possible. Therefore, we work closely with our customers to ensure that their needs are fully understood and met. Our team of experts has a wealth of experience in the industry, which enables us to provide valuable insights and advice to our clients.

CUSTOM ON-SITE TOOLING

We meet our customers’ needs for unique custom extrusions with in-house, custom tool and die design services.

TECHNICAL RESOURCES

We offer several technical resources and PDFs to assist in the design of effective and efficient rubber extrusions.

DESIGN ASSISTANCE

We offer cost effective solutions by achieving the proper performance levels with smart materials selection.