Rubber Extrusions

Rubber Extrusion is a process which forces uncured rubber compounds through a die and into the desired shape. Once extruded it is immediately cured. Our process utilizes a continuous salt bath cure line. The uncured extrusions will run through a salt line at approximately 400˚ F and emerge fully cured, with the different components of the material being cross-linked.

The Basics

Unlike other methods, the extrusion process lends itself well to high volume lineal foot production runs. By using a salt bath cure system, we are not restricted to limited product lengths, such as with an autoclave cure system. Extrusion also allows a higher volume of material to be processed in a shorter time, whereas the molding process produces a set number of parts per cycle. In general, rubber extrusions are produced in accordance with established RMA tolerances.

With our main focus being on custom design manufacturing, there are minimum order requirements. The minimum order requirement will vary with profile size and material. Our production runs are based on at least a full batch of material. Material batch sizes can range from 100 lbs for Silicone up to 500-600 lbs for EPDM and other materials. Sponge compounds will also have a much higher yield than dense compounds.

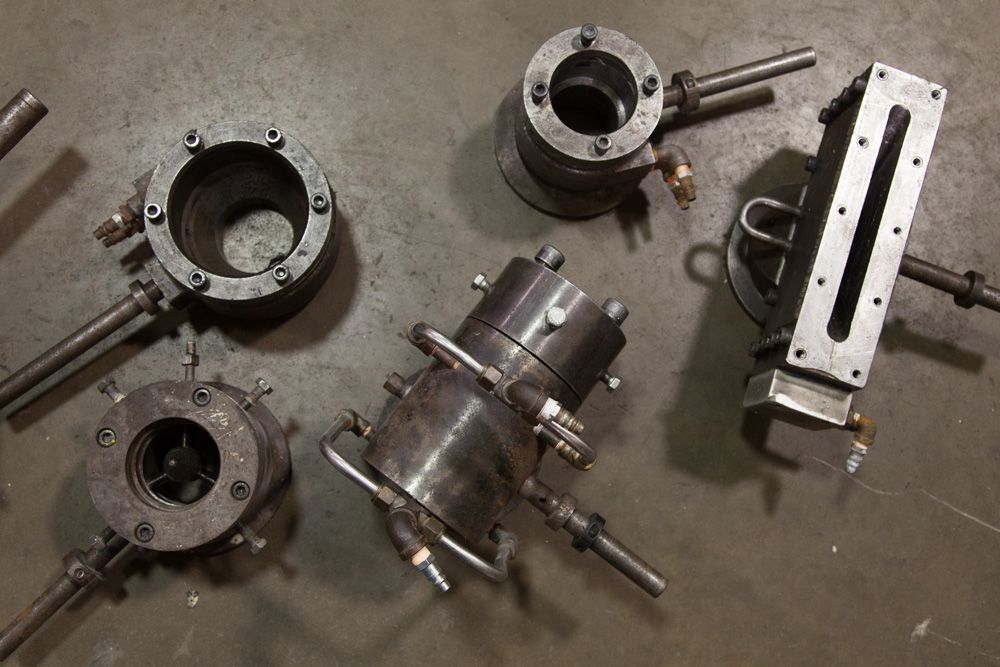

Extrusion Tool & Design Die

An extrusion die is a steel blank that is precisely cut to the shape of the cross-sectional profile of the desired part. Once in place, raw material is forced through the die and cured to create the profile. Due to unique characteristics of different materials, dies are material and durometer specific.

Contact Us today to learn more about our die design services or fill out our RFQ form to get started on your quality rubber products.

Engineered Rubber

- In-house tooling design and production

- custom rubber products and rubber compound design assistance

Value Added Services

- High-speed auto cutting, punching, printing and splicing

- Taping with pressure-sensitive adhesives, mastics, and HATS

- Secondary vulcanization (butt-splice, compression, injection)

Post Production

- Strong SPC facilities

- On-spec and on-time deliveries

- Complete QC from design to finished product

Engineering Resources to

Support Your Project

ELBEX Corporation is committed to providing top-notch support to its customers during the design and manufacturing process. We understand that the success of our clients is directly tied to our ability to provide them with the highest level of service possible. Therefore, we work closely with our customers to ensure that their needs are fully understood and met. Our team of experts has a wealth of experience in the industry, which enables us to provide valuable insights and advice to our clients.

CUSTOM ON-SITE TOOLING

We meet our customers’ needs for unique custom extrusions with in-house, custom tool and die design services.

TECHNICAL RESOURCES

We offer several technical resources and PDFs to assist in the design of effective and efficient rubber extrusions.

DESIGN ASSISTANCE

We evaluate your unique application need and are prepared to offer design assistance and troubleshoot previous issues as needed.