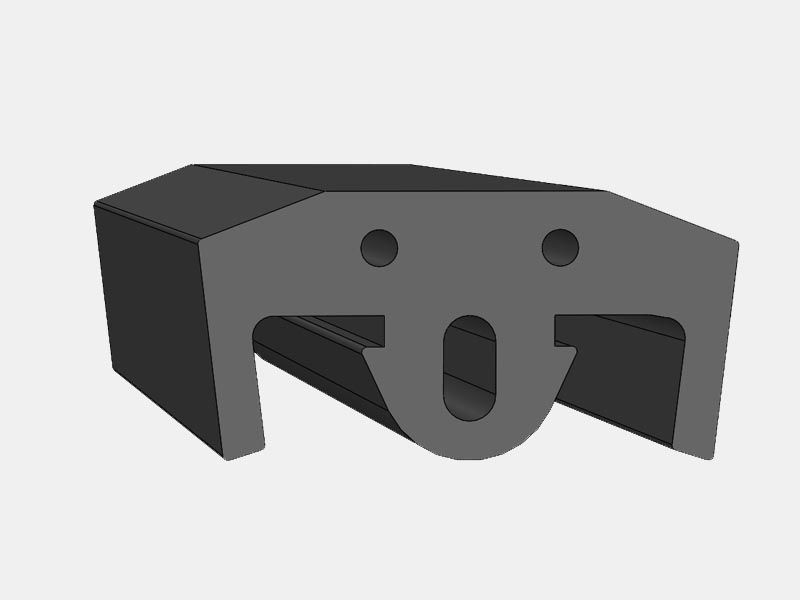

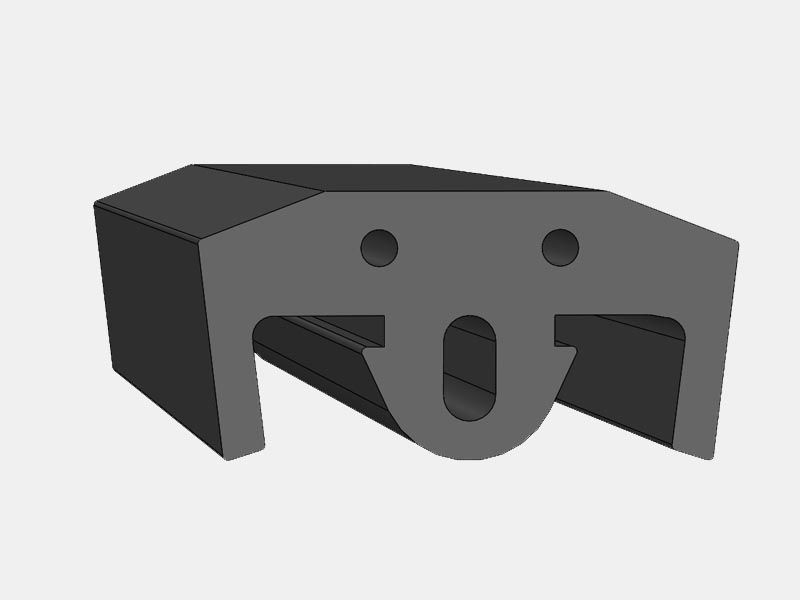

Custom Tooling: Saving You Time and Money

One aspect that sets Elbex apart from other rubber extrusion manufacturers is our ability to offer onsite custom tooling. No two applications are exactly alike, and quite often, this means that standard extrusions simply aren’t going to be enough to get the job done. Here’s how our custom tooling process can help your business save time and money.

Greater Efficiency Means a Faster Turnaround

Processing all of our extrusion, custom tooling, and die design services onsite can dramatically speed up project turnarounds. While it may take weeks to outsource tooling, internal processing means such projects can often be completed in a day or less. With shorter lead times, delivery of the final products can be completed that much sooner, allowing you to put your application to work and achieve your productivity goals.

Cost Savings Passed Along to You

By managing everything in-house and reducing project lead times, our team is able to save a lot of money on tooling and extrusion. We are more than happy to pass these cost savings along to our customers. Onsite production also gives our engineers more direct oversight over every project. This ensures that the finished product meets all applicable quality certification standards. You don’t have to worry about a rubber extrusion not living up to expectations thanks to the high standards of our in-house team. Extrusions that stand the test of time will help you save on maintenance and other costs in the long run.

If you’d like to take advantage of Elbex’s custom tooling services, contact us today. Our skilled engineers are ready to work with you to develop solutions that will fully meet the unique needs of your application.

Want more information?

ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials.

ELBEX CORP

Get In Touch

Phone: 330.673.3233

Fax: 330.673.3235

Email:

info@elbex-us.com

Address: 300 Martinel Dr. Kent, OH 44240

Latest news