Ohio Manufacturer of Butyl, Silicone Rubber, and More!

At Elbex, our Ohio-based team understands how the right material selection can make all the difference for your project. That’s why we offer several different elastomers for extrusion manufacturing! By asking the right questions about the application and its environment, we can help you determine the right compound for your need.

What Compounds Does Elbex Work With?

Elbex offers a wide range of elastomers, including butyl, silicone rubber, nitrile, EPDM, neoprene, natural rubber, and SBR. Each of these compounds has its own unique properties that makes it well suited for different jobs. For example, nitrile offers high resistance to gasoline, hydraulic fluids, and vegetable oils, making it a great fit for automotive applications.

How to Determine the Right Fit

Understanding the specifications of the application and the environment that the rubber extrusion will be operating in will determine the right material for the job. Temperature requirements, chemical exposure, regulatory requirements, the part’s function, and even whether it will be inside or outside can all affect which material is the best fit. By working with a wide range of elastomers, Elbex has the options you need to fulfill your project requirements.

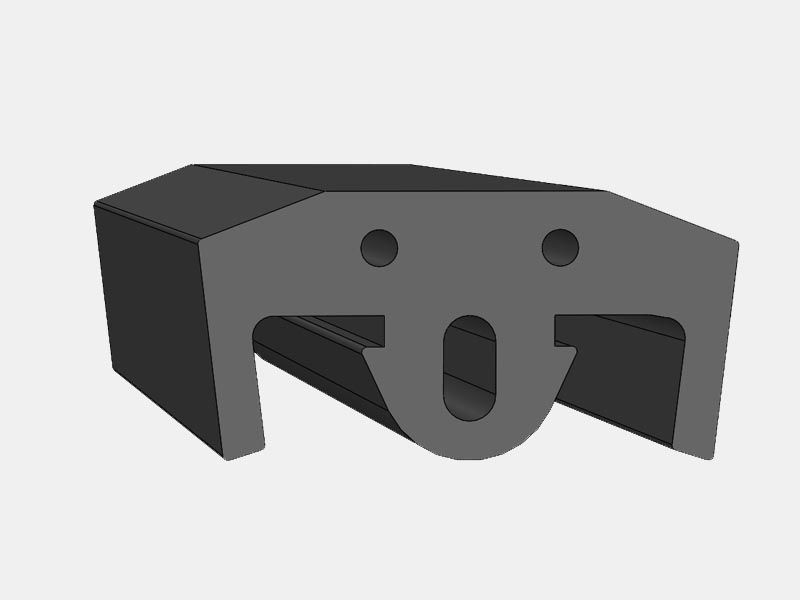

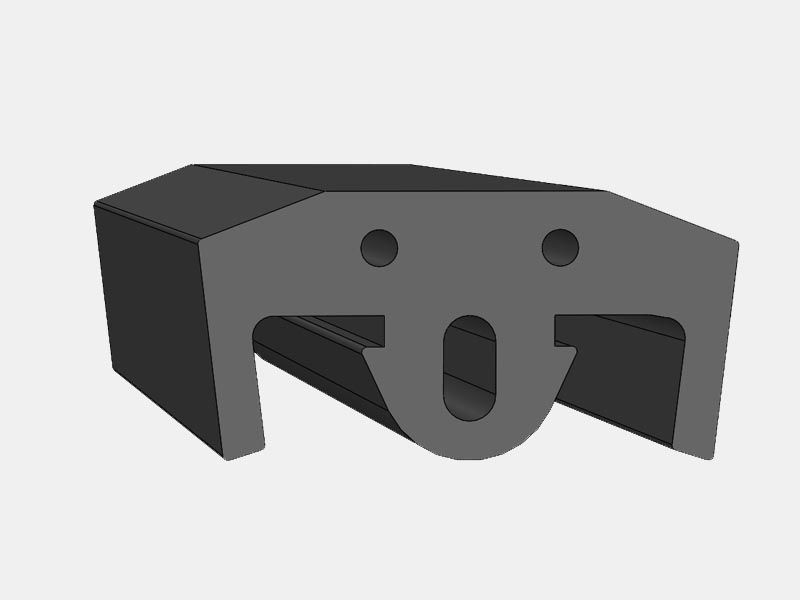

No matter what kind of project you have in mind, Elbex can help you determine the right materials for the job. Our design and engineering team has the experience to produce both custom and standard components that will stand the test of time for any application.

Want more information?

ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials.

ELBEX CORP

Get In Touch

Phone: 330.673.3233

Fax: 330.673.3235

Email:

info@elbex-us.com

Address: 300 Martinel Dr. Kent, OH 44240

Latest news