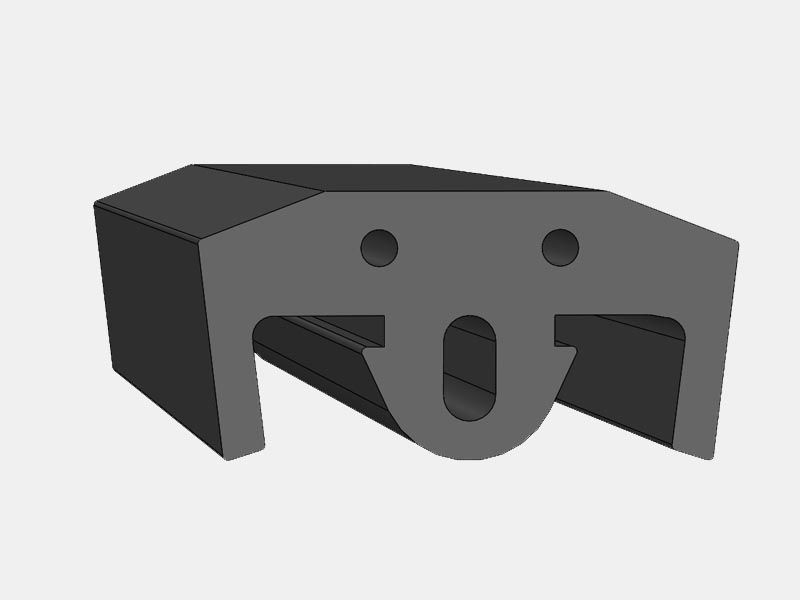

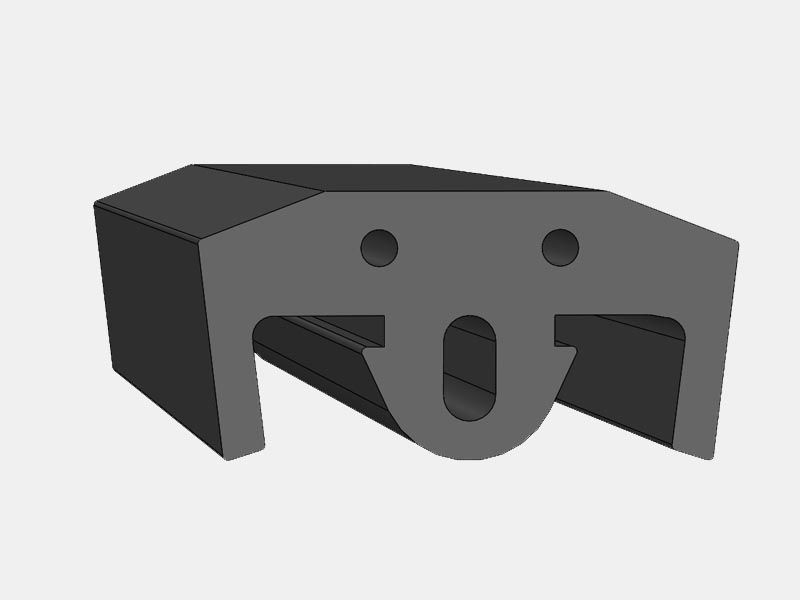

An Overview of Our Custom and Standard Rubber Extrusions

Here at Elbex, our experienced team is able to produce a wide range of both custom and standard rubber extrusions. By understanding our capabilities, you will be better able to determine if we can assist with the needs of your application.

Our Production Process

Our facility is capable of producing rubber profile extrusions, cord, tubing, and sheeting ranging from 1/16 of an inch to 18 inches in width. We use continuous vulcanization (salt-bath curing) to achieve quality results using a wide range of materials, including EPDM, nitrile, silicone, butyl, TPR, and urethane. These elastomers are available in a variety of rubber profiles, and custom batch mixing and color matching are also available. Tooling design and production are completed in-house. All manufacturing is designed to meet ASTM, AMS, SAE, and military specifications.

Value-Added Services

To further enhance our offerings for our clients, our facility can also provide auto-cutting, punching, splicing, and pinching, secondary vulcanization, taping with pressure-sensitive adhesives, and more. These additional services, paired with complete quality control from the design phase to the finished product, ensure you get the results you need with a timely turnaround.

If you’re not sure whether we’d be a good fit for your project, feel free to reach out using our online requisition form. Our team of engineers will be happy to assist you and help you determine the best options for your application’s needs.

Want more information?

ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials.

ELBEX CORP

Get In Touch

Phone: 330.673.3233

Fax: 330.673.3235

Email:

info@elbex-us.com

Address: 300 Martinel Dr. Kent, OH 44240

Latest news