Sustainability in Manufacturing: How Elbex is Leading the Way

In today’s world, sustainability has become more important than ever before. Every company has a responsibility to limit its impact on the environment. This isn’t just the right thing to do — it’s what today’s customers are expecting! Here’s a closer look at how Elbex is leading the way in environmentally responsible manufacturing processes.

The Importance of Sustainability in Manufacturing

As mankind’s impact on the environment has become more apparent, more and more people are preferring to do business with companies that value sustainability. Quite often, this even comes down to the products you use for your own manufacturing projects.

By using materials that were sustainably manufactured (such as rubber extrusions), you send a message to your consumers regarding your commitment to lower your environmental impact. Environmentally friendly business practices can actually encourage people to do more business with you. You help the planet, and your bottom line.

What Elbex Is Doing

At Elbex, our company is actively striving to approach our processes in a more sustainable and cost-efficient way. For example, by managing all tooling and die work on-site, we are able to conserve energy that would otherwise be used to transport materials and finished products.

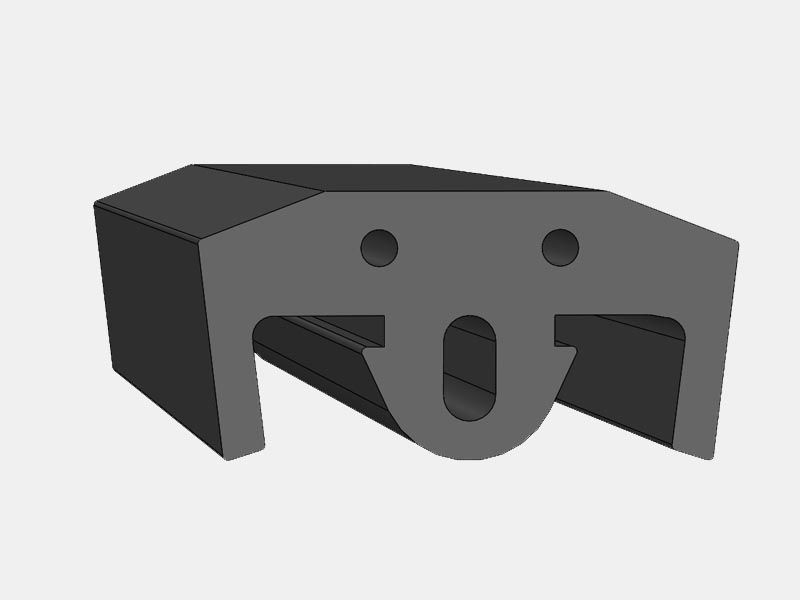

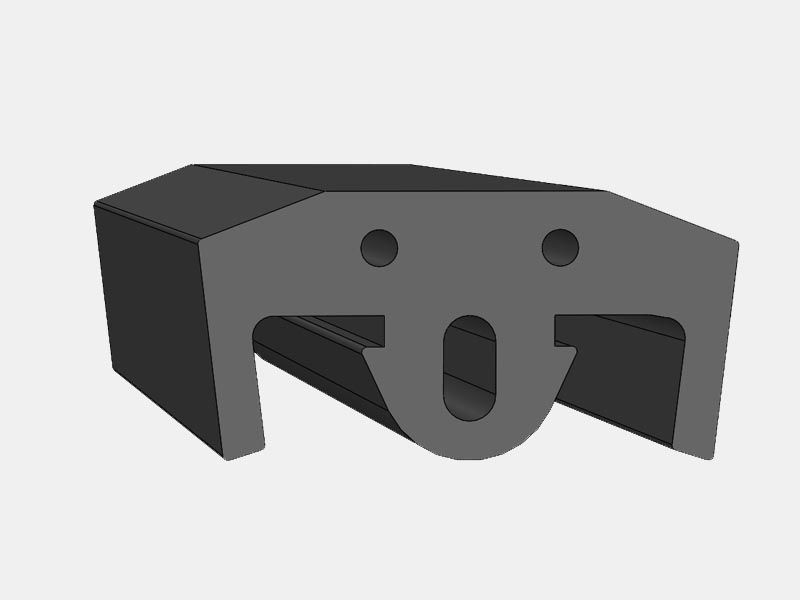

Our focus on custom rubber products, with the ability to manufacture both small and large product runs, also helps us reduce waste and ensure that all of our materials are used effectively. These practices don’t just help us minimize our environmental impact — they also lower manufacturing costs, which allows us to pass savings on to you.

For both standard and custom rubber extrusions, you can count on Elbex to deliver high-quality work that also accounts for our impact on the environment. Our team will work closely with you from start to finish to ensure that you get the results you need for your unique project. Contact us today to learn more.

Want more information?

ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials.

ELBEX CORP

Get In Touch

Phone: 330.673.3233

Fax: 330.673.3235

Email:

info@elbex-us.com

Address: 300 Martinel Dr. Kent, OH 44240

Latest news