What is Natural Rubber?

Crude natural rubber is found in the juices of many plants (shrubs, vines, and trees), the principal of which is the Hevea Brasiliensis tree, native to Brazil. After the latex is processed, natural rubber becomes an elastomer with excellent mechanical properties.

Natural Rubber has a typical service temperature range between –67° F and +180° F.

ADVANTAGES:

Natural rubber has excellent tensile, elongation, tear resistance, resilience, and electrical insulation. Natural rubber’s high resilience is only outperformed by some of the more recent manmade polyisoprenes and polybutadienes. Natural rubber exhibits excellent resistance to water and cold flow. Natural rubber has low compression set and can be bonded to a wide range of materials. It also has good flexing qualities at low temperatures that are better than most synthetics, but it is not as good as silicone or some of the special butadiene and SBR compounds. Natural rubber has superb abrasion resistance when it is compounded with carbon black.

LIMITATIONS:

Natural rubber deteriorates when exposed to oils, fuels, solvents, petroleum derivatives, and hydraulic fluids. Without special additives, natural rubber has poor resistance to sunlight, oxygen, ozone, and high temperatures.

COMMON APPLICATIONS:

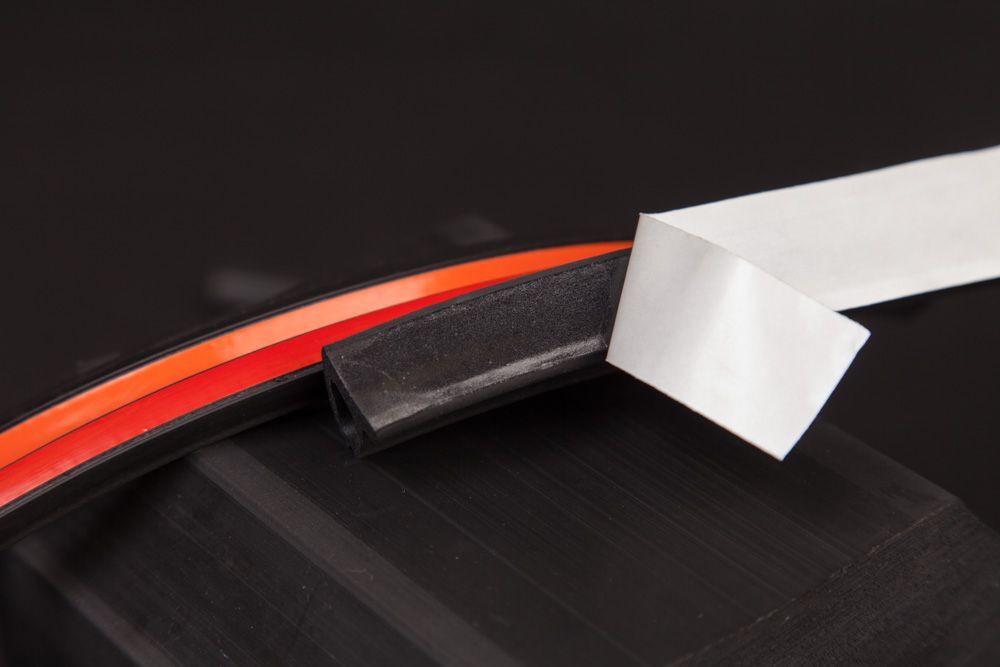

Natural rubber can be easily bonded to a wide variety of materials, including fabric and metal. Natural rubber is widely used where many types of acids and bases, except those types that are highly oxidizing, are present. Common applications include tires, tubing, gaskets, belts, hoses, seals, shock mounts, rolls, vibration isolators, electrical components, bumpers, and drive wheels.

Durometer

The hardness of rubber compounds is measured by the Shore A durometer; the higher the durometer number, the harder the compound. Softer compounds stretch easier and seal better on rough surfaces. Harder compounds offer greater abrasion/extrusion resistance.

Typical Questions Asked

- What is the application or function of the part?

- Is there a target cost per part that should be considered?

- Will the part be located inside or outside?

- What, if any, are the temperature requirements?

- Is there exposure to specific chemicals?

- Does the part need to meet any regulatory requirements?

Now that you know what materials your project needs, fill out a request for a quote form to get started.

For more detailed information on material selection, please see our engineering technical information page. Several PDF data sheets are available for download.

Engineering Resources to

Support Your Project

ELBEX Corporation is committed to providing top-notch support to its customers during the design and manufacturing process. We understand that the success of our clients is directly tied to our ability to provide them with the highest level of service possible. Therefore, we work closely with our customers to ensure that their needs are fully understood and met. Our team of experts has a wealth of experience in the industry, which enables us to provide valuable insights and advice to our clients.

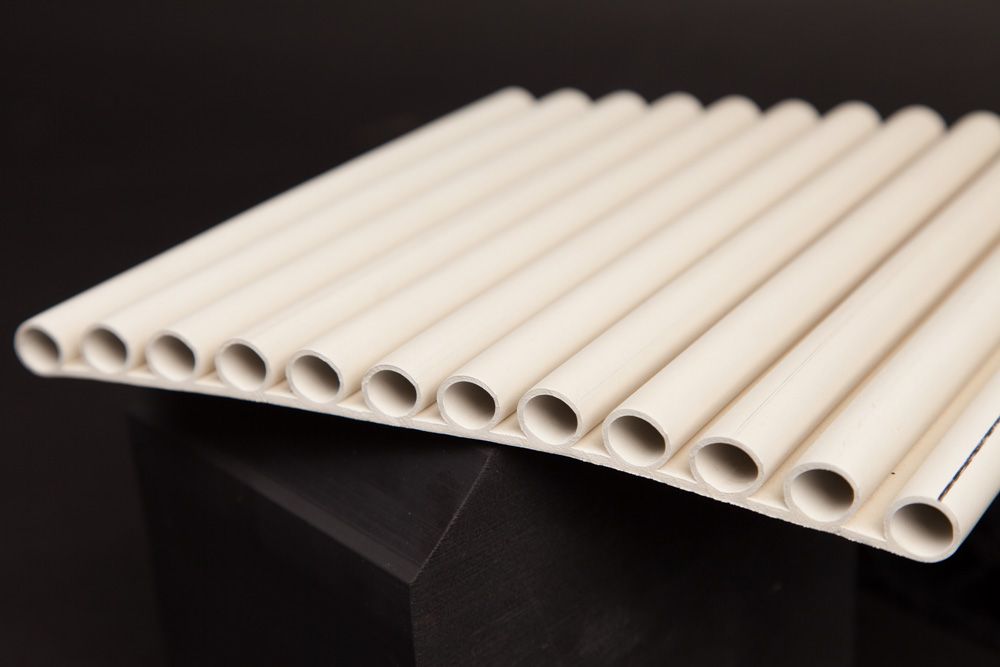

CUSTOM ON-SITE TOOLING

We meet your needs for custom extrusions with in-house, custom tool and die design services.

TECHNICAL RESOURCES

Find technical resources and to assist in the design of effective and efficient rubber extrusions.

DESIGN ASSISTANCE

We're ready to offer design assistance and troubleshoot old problems for your unique project.