What is Neoprene?

Neoprene was created in 1930 by DuPont as an air and oil resistant substitute for natural rubber. It was the first mass produced synthetic rubber. Neoprene is a polymer of chloroprene and is considered a general or all-purpose rubber. Neoprene is available in many varieties including non-sulfur modified "W" and the more common sulfur modified "GN" types. Neoprene has a typical service temperature range between –50° F and +275° F.

Elastomers Offered

ADVANTAGES:

Neoprene is known for its versatility. It provides good resistance to moderate exposure to ozone, sunlight, oxidation, weather, oils, gasoline, greases, solvents, petroleum oils, animal and vegetable oils, compression set, silicone oil, refrigerants, ammonia, carbon dioxide, water, and steam. Certain compounds of neoprene are flame resistant and will not support combustion. The tear resistance is equal to natural rubber at room temperature; at elevated temperatures tear resistance is poor but can be improved to some extent by compounding with reinforcing materials. Resilience and abrasion strength are good. Adhesion to metals and fabrics is very good.

LIMITATIONS:

The cost of neoprene is its greatest disadvantage. It is a good multipurpose rubber, but there are other types that offer much better oil, ozone, weather and oxidation resistance at a lower cost when they are used for specific applications. Neoprene has poor resistance to strong oxidizing acids, esters, ketones, chlorinated, aromatic, and nitro hydrocarbons.

COMMON APPLICATIONS:

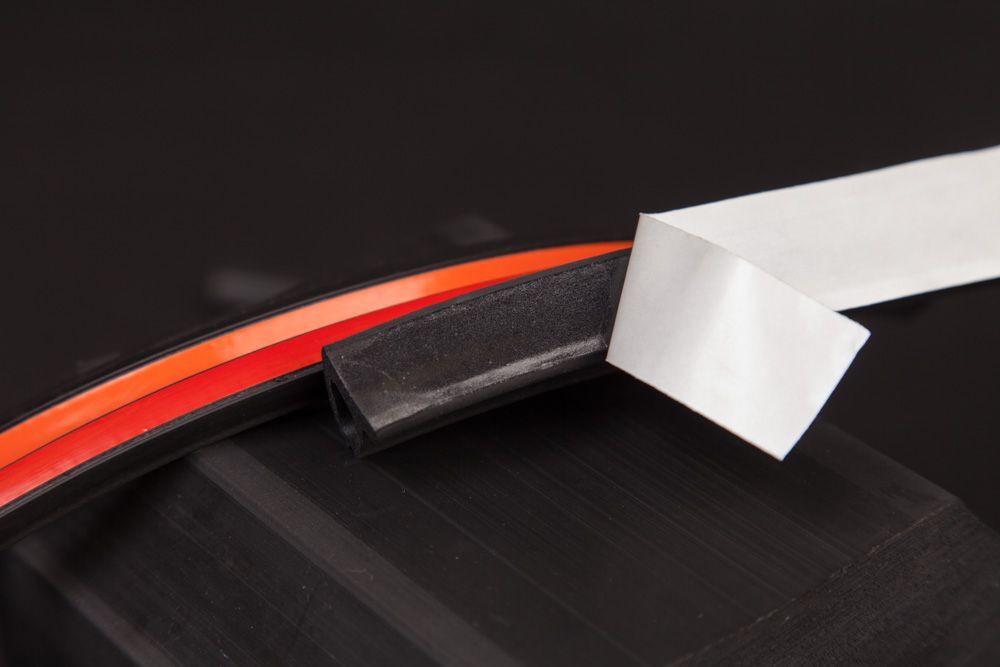

Neoprene is primarily used in applications when the seal is exposed to weathering refrigerants, silicate ester lubricants and high aniline point petroleum oils. Neoprene can be formulated for use in mass transit industries due to its ability to meet ASTM c1166, e162, e662 and SMP800C standards. Common applications include refrigeration seals, Freon/air conditioning, motor mounts, engine coolants, petroleum and chemical tank linings, automotive gaskets and seals, and weather stripping.

Engineering Resources to

Support Your Project

ELBEX Corporation is committed to providing top-notch support to its customers during the design and manufacturing process. We understand that the success of our clients is directly tied to our ability to provide them with the highest level of service possible. Therefore, we work closely with our customers to ensure that their needs are fully understood and met. Our team of experts has a wealth of experience in the industry, which enables us to provide valuable insights and advice to our clients.

CUSTOM ON-SITE TOOLING

We meet your needs for custom extrusions with in-house, custom tool and die design services.

TECHNICAL RESOURCES

Find technical resources and to assist in the design of effective and efficient rubber extrusions.

DESIGN ASSISTANCE

We're ready to offer design assistance and troubleshoot old problems for your unique project.