Our Rubber Setting Blocks and Their Applications

At Elbex, our team is proud to be able to produce a wide range of high-quality rubber extrusions — including setting blocks. Here is a closer look at what setting blocks do, and the role they play in a variety of industries.

Setting Block Basics

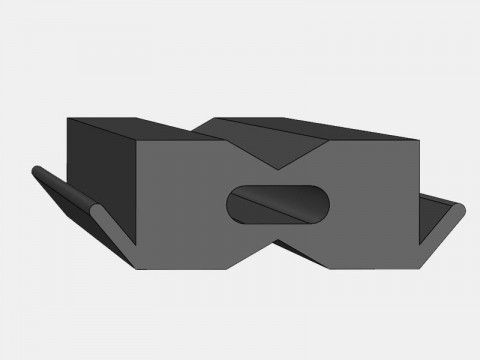

Setting blocks are used to position different materials in an application. As part of this, they help minimize uneven surfaces and reduce vibration between the different surfaces. Setting blocks are produced in a variety of shapes — ranging from simple rectangular profiles to more detailed options that track into channels. Setting blocks are most frequently used for glazing applications.

Key Industries That Use Setting Blocks

Setting blocks are most used in industrial manufacturing, construction, and architecture. For example, setting blocks may be used to help set glass within aluminum channels to seal fenestration systems or architectural facades. Materials must be selected based on expected environmental exposure and other potential hazards. The right materials and dimensions will ensure that the finished setting block stands the test of time and delivers reliable performance.

Whether you need setting blocks or another rubber extrusion for your work, you can count on Elbex to deliver high-quality products that will deliver the performance you need. Our capabilities include both standard and custom rubber extrusions, with custom tooling, design assistance, and a wide range of materials to ensure you get a finished product that will provide lasting performance. Contact us today to learn more.

Want more information?

ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials.

ELBEX CORP

Get In Touch

Phone: 330.673.3233

Fax: 330.673.3235

Email:

info@elbex-us.com

Address: 300 Martinel Dr. Kent, OH 44240

Latest news