Precision in Rubber: Your Custom Extrusion Solution, Step-by-Step

Custom rubber extrusions play a vital role across various industries by creating watertight and airtight barriers, eliminating vibrations, and securing components. As a leader in custom rubber extrusion manufacturing, Elbex can ensure a precise fit for a wide range of unique applications. Here’s how our processes work.

Phase 1: Initial Consultation and Design

Our work begins when clients contact us to explain their needs or share their pre-existing sketches, drawings, or samples. These initial conversations are important in ensuring a collaborative effort that meets your use needs. Elbex’s design assistance and reverse engineering capabilities play a key role in this phase.

Phase 2: In-House Die Creation

Once a design has been finalized, we develop an appropriate extrusion die to create custom shapes for manufacturing. In-house die creation allows for a more cost-effective manufacturing process with a faster turnaround, while also enabling precise, high-quality outcomes. Each die is tailored to specific materials and durometers to achieve desired outcomes.

Phase 3: Extrusion Production

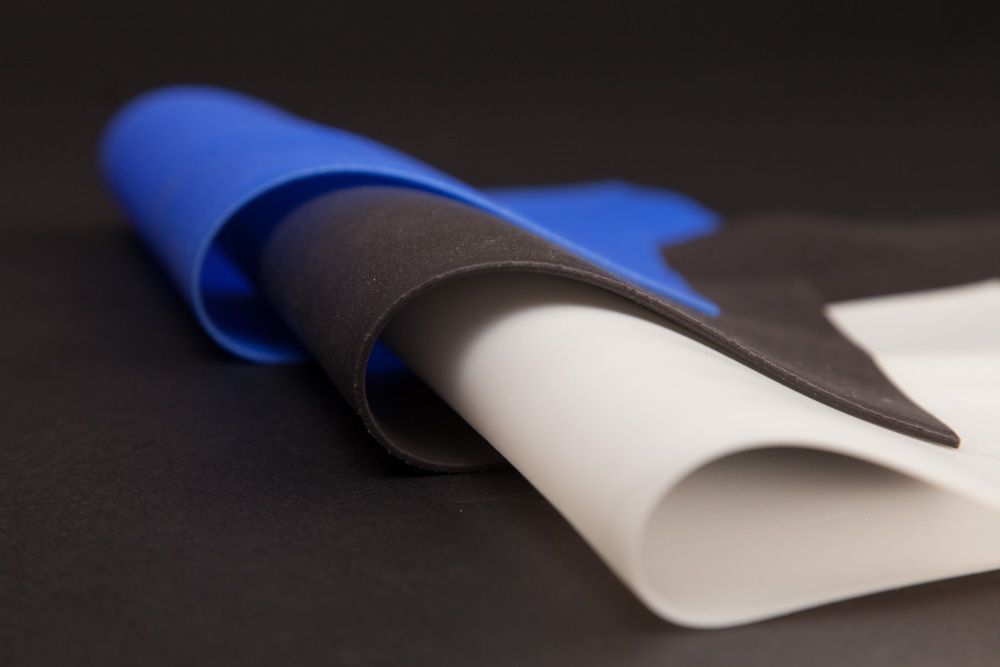

After dies have been created, rubber elastomers are extruded in continuous lengths and cut and cured according to project specifications using a salt bath cure system. Elbex works with a wide range of elastomers, including natural rubber, butyl, EPDM, silicone, neoprene, and more.

Phase 4: Delivery and Support

Elbex is committed to providing timely delivery and ongoing support for all orders. Clients are encouraged to reach out for troubleshooting or design assistance, especially if things don’t seem quite right after delivery. Our goal is to provide a rapid turnaround with top-quality products and service.

With a comprehensive process that can be tailored to your specific application, Elbex is the go-to solution for custom rubber extrusions. Fill out our

RFQ form today to get started on your project.

Want more information?

ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials.

ELBEX CORP

Get In Touch

Phone: 330.673.3233

Fax: 330.673.3235

Email:

info@elbex-us.com

Address: 300 Martinel Dr. Kent, OH 44240

Latest news